Our products are fully costumizable and bespoke crafted

WHY CHOOSE US?

LASER CUTTING

We offer laser cutting on our high-performance laser cutting machines, with a short deadline, in good quality, at a favorable price.

● Maximum board size: 3000 x 1500 mm

● Cuttable sheet materials and their maximum thickness:

● Stainless steel - Lv25 mm

● (Carbon steel - Lv25 mm)

● Aluminium - Lv10 mm

● Pipe dimensions:

● Ø20 mm - Ø160 mm

● Maximum wall thickness up to 4 mm (stainless steel only)

PLATE MACHINING

We also undertake the machining of stainless steel sheets from Lv0.8 to 8 mm.

Cutting to size with straight contours (sheet metal cutting):

● Lv3 up to 2000 mm width

● Lv2 up to 3000 mm width

Double-sided deburring

Rolling of plates

● Ø65 mm to Ø200 mm in widths up to 1000 mm (up to Lv2)

● Above Ø210 - up to 2000 mm width (up to Lv3)

● Above Ø350 - up to 3000 mm width (up to Lv6)

● Splates are joined by line welding up to 4 mm thick up to 3000 mm long

● Bending of plates up to 6 mm thickness, 3000 mm length (with precision Amada bending machines)

● Pressing in the range of 10-500 tonnes

● Finishing of desired surfaces by sanding, dry and wet bead blasting

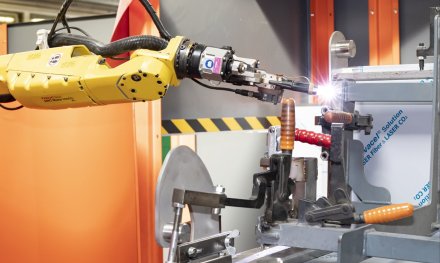

WELDING

The professional supervision of our welders' work is carried out - in addition to external organisations - by continuously trained experienced welders, welding specialist and welding engineer.

Our company has 2 welding certifications:

● DIN EN ISO 3834-2 (TÜV Rheinland)

● AD 2000-Merkblatt HP 0 (TÜV Rheinland)

● The standard technology is TIG (145), our welding machine fleet consists of 65 inverter TIG power sources with 160A, 240A and 500A power.

Continous wired welding technology MIG/MAG (131, 135) has also been introduced in the production.

With our long seam welding machine, we are able to TIG (145) weld 3000 mm plate length (up to Lv4), we are also equipped for rolling and edge bending of the same length size.

● 2 welding robot cells were also commissioned.

● We have also increased our grinding capacity and capabilities with the addition of a robot.

● We undertake large series grinding by individual agreement.

English

English